Bentonite

PROPERTIES:

Ways to contact us:

Delivery Terms: FOB/CIF/CFR/CPT/FCA

Bentonite is a naturally occurring clay mineral primarily composed of montmorillonite, renowned for its exceptional swelling, binding, and absorption properties.

At CNB Petro, we supply high-grade Bentonite tailored for demanding industrial applications — from construction and drilling to metal casting and environmental protection.

Key Features of Bentonite:

- High Swelling Capacity: Expands multiple times its dry volume when hydrated, ideal for sealing and stabilizing.

- Superior Binding Strength: Ensures structural integrity in foundry molds and iron ore pelletizing.

- Thermal Stability: Maintains performance under extreme temperatures.

- Adsorption Efficiency: Captures impurities, toxins, and heavy metals in filtration and purification systems.

Industrial Applications:

- Oil & Gas: Used in drilling fluids to lubricate, cool, and stabilize boreholes.

- Construction: Applied in waterproofing, tunnel boring, and slurry walls for

- geotechnical engineering.

- Foundry: Acts as a binder in molding sands for precision metal casting.

- Iron & Steel: Facilitates iron ore pellet formation for blast furnace operations.

- Environmental Protection: Forms impermeable barriers in landfill liners and hazardous waste containment.

Available in sodium and calcium grades, our Bentonite products are engineered to meet international standards and customized to your operational needs.

Sodium Bentonite:

Sodium Bentonite is a highly absorbent form of bentonite clay, prized for its swelling capacity and sealing properties. It’s primarily composed of the mineral montmorillonite and contains a high concentration of exchangeable sodium ions, which give it unique performance advantages across various industries.

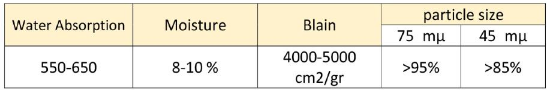

Physical specifications:

Key Properties of Bentonite:

- Exceptional Swelling: Can expand up to 15–20 times its dry volume when hydrated.

- Strong Gel Formation: Creates stable suspensions, ideal for drilling fluids and slurry walls.

- Low Permeability: Forms impermeable barriers, making it perfect for sealing and containment.

- High Cation Exchange Capacity (CEC): Useful in purification and environmental remediation.

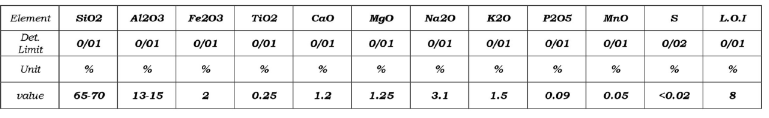

Chemical Specification of Bentonite:

Industrial Applications:

- Oil & Gas Drilling: Used in drilling muds to stabilize boreholes, cool drill bits, and transport cuttings.

- Civil Engineering: Applied in slurry walls, tunnel boring, and foundation sealing.

- Environmental Protection: Forms liners for landfills, ponds, and hazardous waste containment.

- Foundry: Acts as a binder in molding sands for metal casting. Agriculture: Improves soil structure and water retention in arid regions. Sodium Bentonite is often preferred over calcium bentonite due to its superior swelling and sealing

- capabilities. It’s available in various mesh sizes and moisture levels, depending on the application.

- Pelletizing Iron Ore, Cat Litter, Asphalt adhesive, Animal feed Toxin binder

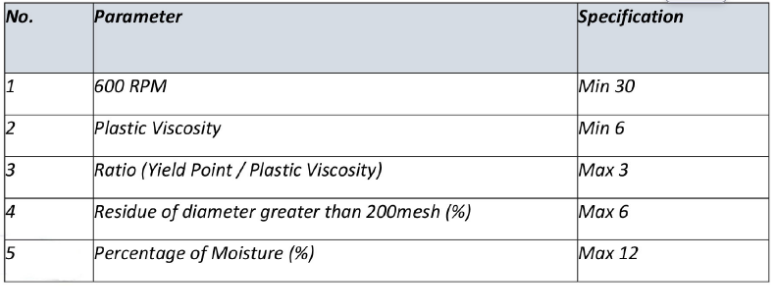

API Bentonite:

API Bentonite refers to a specialized grade of bentonite clay that meets the strict performance standards set by the American Petroleum Institute (API) — specifically for use in oil and gas drilling operations.

Key Characteristics of API Bentonite:

- High Swelling Capacity: Absorbs water and expands significantly, helping to stabilize boreholes.

- Viscosity Builder: Enhances the thickness of drilling fluids, improving their ability to carry cuttings to the surface.

- Low Fluid Loss: Minimizes the escape of drilling fluid into surrounding formations.

- Suspension Stability: Keeps solids suspended in the mud, preventing sedimentation.

Reviews

There are no reviews yet.