High Density Polyethylene Natural (Grade: NI1030)

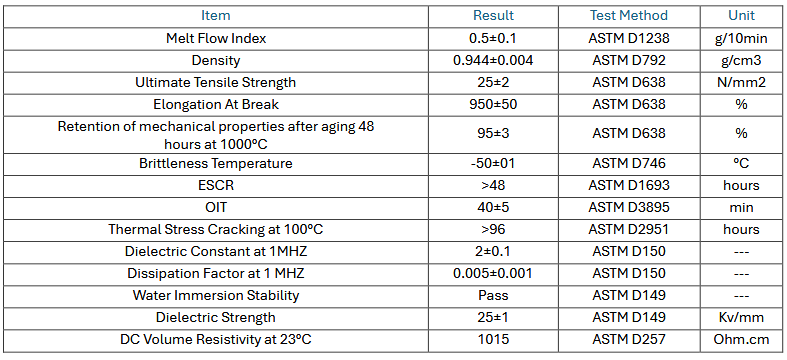

PROPERTIES:

Ways to contact us:

Delivery Terms: FOB/CIF/CFR/CPT/FCA

Grade: NI1030

HIGH DENSITY PLOYETHYLENE FOR INSULATING TELEPHONE SINGLE WIRE AT HIGH SPEED.

High Density Polyethylene (Natural) – Grade: NI1030 is a polyethylene compound specifically developed for solid insulation of single telephone wires in high-speed extrusion processes. It is particularly suited for use as insulation in petroleum-filled telephone cables and is also well-suited for use as the outer layer in foam-skin cable constructions.

APPLICATIONS:

Grade NI1030 is designed for high-speed insulation of telephone single wires—operating effectively at extrusion speeds of up to 2400 m/min. It is ideal for use in both dry core and petroleum jelly-filled cables and also serves well as the outer skin in foam-skin constructions.

FEATURES:

- Excellent electrical insulation properties

- Optimized for high-speed extrusion (up to 2400 m/min)

- Superior melt strength and stability

- Smooth surface finish for consistent wire coating

- Good mechanical strength and flexibility

- Suitable for both dry core and petroleum jelly-filled cables

- Compatible as outer skin in foam-skin constructions

PROPERTIES:

PROCESSING CONDITIONS:

Grade NI1030 is suitable for processing under a wide range of conditions and supports very high extrusion speeds, typically up to 2400 m/min. For standard extrusion equipment, the following settings are recommended to ensure optimal insulation quality. Using heated water (up to 50 °C) in the initial section of the cooling trough can enhance adhesion to the conductor.

Tooling:

Pressure tooling is generally necessary, and die diameters are usually matched closely to the final wire size (“on size” tooling).

Typical Processing Parameters:

- Barrel Temperature: 165 – 210 °C

- Die Head Temperature: ~220 °C

- Melt Temperature: 220 – 230 °C

- Conductor Preheating Temperature: 100 – 115 °C

STORAGE:

Grade NI1030 is available in bulk packaging, octabins, and bags. When stored in its original, unopened packaging under clean and dry conditions at temperatures between 10°C and 30°C (50°F to 85°F), the product maintains a shelf life of up to 24 months from the production date. Storage conditions significantly affect the material’s quality and performance—exposure to extreme conditions may lead to degradation. To maintain product integrity, it is recommended to follow a First-In, First-Out (FIFO) stock rotation system.

SAFETY:

CNB is dedicated to reducing the environmental impact of its products. We embrace Design for Circularity (DfC) and Design for Recycling (DfR) to help conserve natural resources and minimize environmental impact throughout the entire product lifecycle—from production and usage to end-of-life. DfR ensures that our materials are designed for effective recyclability while maintaining high performance and efficiency. For more details on our sustainability initiatives and approach to Design for Recycling, please visit our website: www.cnbpetro.com .

Disclaimer:

The product(s) referenced in this document are not intended for use in medical, pharmaceutical, or healthcare applications, and CNB does not endorse or support their use in such areas. While the information provided is believed to be accurate and reliable as of the publication date, CNB makes no guarantees regarding its accuracy or completeness and assumes no liability in this regard.

CNB provides no warranties beyond those explicitly stated in this document. Nothing contained herein should be interpreted as a guarantee of merchantability or suitability for any specific application. It is the customer’s responsibility to evaluate and test the product to determine its appropriateness for their specific requirements. Customers are also solely responsible for the safe, lawful, and appropriate use, processing, and handling of the product. CNB cannot accept any liability for the use of its products in combination with other substances or materials unless such use is explicitly addressed in the referenced test methods or documentation. The information provided applies only to CNB products used independently, unless otherwise specified.

Reviews

There are no reviews yet.