High Density Polyethylene (6B Black)

PROPERTIES:

Ways to contact us:

Delivery Terms: FOB/CIF/CFR/CPT/FCA

HIGH DENSITY POLYETHYLENE FOR JACKETING OPTICAL FIBER CABLES.

The material covered by this specification should conform to ASTM D-1248 type III; class C, category 4 or 5, grade E8 latest edition. The material should contain a non-staining antioxidant

system.

The melt flow rate for processed material in cable should not show a maximum 50% increase from raw material. The material should be stabilized against thermal and shear degradation and ensure long-term aging properties. The material furnished under this specification shall be free from dust, dirt, metallic particles, chaff streamers and all other foreign materials and as uniform in appearance as good commercial practice will permit. Pellets furnished shall be approximately 3mm or less on all dimensions.

APPLICATIONS:

HDPE (black) 6B is a high-density polyethylene jacketing compound in black, developed using CNB’s proprietary bimodal process technology. This innovative process enables the creation of polymers with properties that exceed traditional melt flow rate and density limits, resulting in enhanced processability, minimized shrinkage, excellent mechanical strength, and high resistance

to environmental stress cracking (ESCR). The compound includes 2.5% uniformly distributed carbon black to ensure exceptional protection against UV radiation and weathering. Suitable for use as a jacketing material in optical fiber cables.

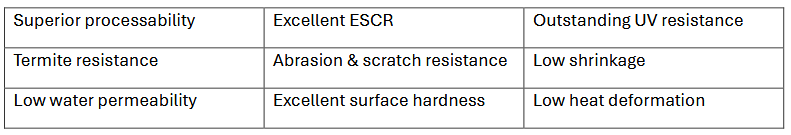

FEATURES:

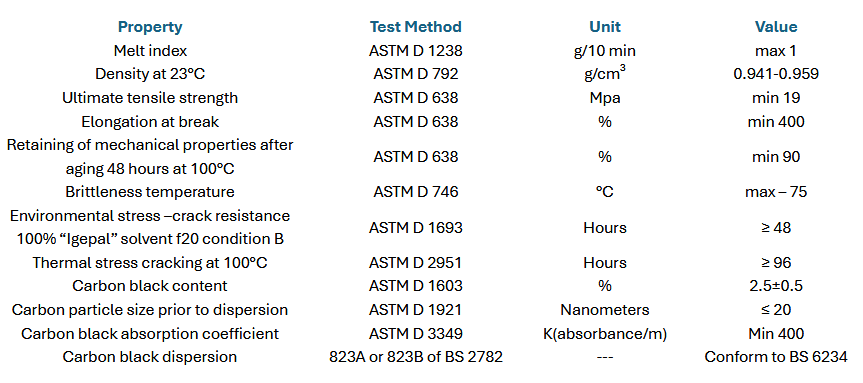

PROPERTIES:

PROCESSING CONDITIONS:

HDPE (black) 6B delivers a high-quality surface finish and supports a wide processing window. It is compatible with most extrusion equipment typically used for PVC or PE processing. To reduce shrink-back, it is highly recommended to use gradient cooling, starting with hot water at a minimum temperature of 60°C in the initial section of the cooling trough. If preheating or drying is applied, the maximum allowable temperature should not exceed 90°C.

STORAGE:

Packaging: Available in bulk, octabins, and bags. HDPE (black) 6B has a shelf life of 24 months from the date of manufacture, provided it is stored in its original, unopened packaging under clean, dry conditions at temperatures between 10°C and 30°C (50°F to 85°F). Storage conditions can impact the material’s quality and performance—extreme environments may degrade its properties. To maintain optimal quality, it is advisable to follow a First-In, First-Out (FIFO) stock rotation system.

SAFETY:

CNB is dedicated to reducing the environmental impact of its products. We embrace Design for Circularity (DfC) and Design for Recycling (DfR) to help conserve natural resources and minimize environmental impact throughout the entire product lifecycle— from production and usage to end-of-life. DfR ensures that our materials are designed for effective recyclability while maintaining high performance and efficiency. For more details on our sustainability initiatives and approach to Design for Recycling, please visit our website: www.cnbpetro.com.

Disclaimer:

The product(s) referenced in this document are not intended for use in medical, pharmaceutical, or healthcare applications, and CNB does not endorse or support their use in such areas. While the information provided is believed to be accurate and reliable as of the publication date, CNB makes no guarantees regarding its accuracy or completeness and assumes no liability in this regard. CNB provides no warranties beyond those explicitly stated in this document. Nothing contained herein should be interpreted as a guarantee of merchantability or suitability for any specific application.

It is the customer’s responsibility to evaluate and test the product to determine its appropriateness for their specific requirements. Customers are also solely responsible for the safe, lawful, and appropriate use, processing, and handling of the product.

CNB cannot accept any liability for the use of its products in combination with other substances or materials unless such use is explicitly addressed in the referenced test methods or documentation. The information provided applies only to CNB products used independently, unless otherwise specified.

Reviews

There are no reviews yet.