Calcined anthracite (injectable)

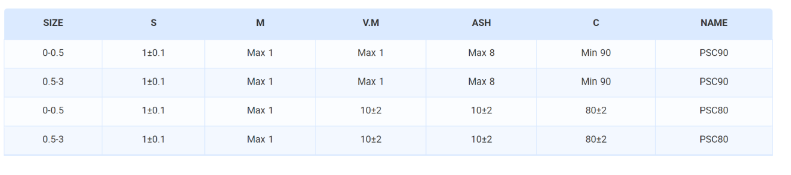

PROPERTIES:

Ways to contact us:

Delivery Terms: FOB/CIF/CFR/CPT/FCA

This product, which is the main production of this company, is the result of concentration, crushing and heat treatment on anthracite coal, which is a suitable alternative to calcined petroleum coke (CPC) in the electric arc furnace steel industry due to market needs and supply constraints in the world.

This product, which is the main production of this company, is the result of concentration, crushing and heat treatment on anthracite coal, which is a suitable alternative to calcined petroleum coke (CPC) in the electric arc furnace steel industry due to market needs and supply constraints in the world. Among the advantages of this product compared to the cokes available in the market, the following can be mentioned:

- More absorption than metallurgical coke, which leads to reduced consumption.

- Reducing the production of iron oxide in slag and thus increasing the production efficiency

- and reducing the slag.

- Reducing Tap to Tap time.

- Reducing additive loss in FTP.

- Reduction of transportation costs (15%) due to significant reduction in ash content.

- Greater compatibility with equipment and reduction of environmental pollution due to reduced sulfur content.

The advantages of this product over CPC are:

- Dramatic reduction in prices by at least a third

- Slight increase in consumption up to 15%

- Reduced shipping costs and customs duties due to short distances

Calcined anthracite (injectable)

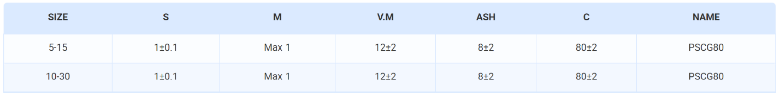

Granular coke:

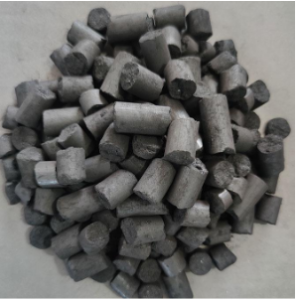

Granular coke is the result of the granulation process of fine-grained coke. This product is combined with standard special briquetting adhesives in a process and then under a certain pressure and temperature with pre-determined molds in the form of hardened granules. Among the advantages of this product, high density (high mechanical strength) and significant reduction of ash under 10% and sulfur under 1%, as well as unified dimensions can be mentioned. Due to the excessive increase in the price of metallurgical coke, sizes 5-15mm and 10-30mm, which have been widely used in the steel and casting industries, this product is a suitable alternative.

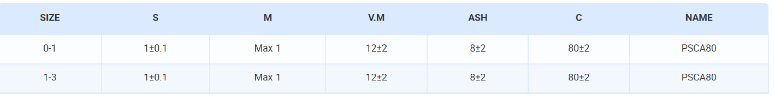

Anti-wear anthracite:

As many steel companies tended to use crude anthracite instead of calcined anthracite, after consumption, they realized that the amount of crude anthracite wear for equipment is higher than oil coke and metallurgy. Now, due to technical knowledge and research in this aspect, CNB Company has started to produce anti-

wear anthracite coal. This product no longer damages industrial devices and equipment due to its anti-wear properties, and it is also not necessary to spend a lot of money to maintain, repair or replace abrasive surfaces.

This can be a vision for the relevant industries so that by consuming this product, they no longer have to worry about the degradability of the equipment and avoid spending a lot of money.

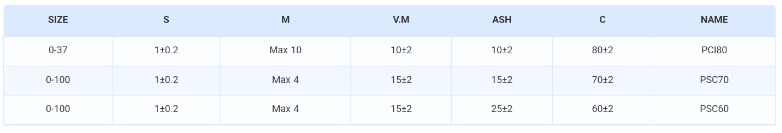

Coal and Concentrate (PCI):

Thermal coal is one of the types of coal and a sub-branch of bituminous coal, which according to its properties and characteristics, it can be used in certain cases. Thermal coal is divided into two categories, low calorific value coal (LOW CTE) and high calorific value coal (HIGH CTE). The reason for this difference is related to the stages of coal transformation in the earth. This coal has a lower coking property than coking coal, so it has a more reasonable price. Basically, the sulfur content of hot coals is less than that of coking coals. It is worth mentioning that sulfur absorbs heat in the form of sulfate when it burns and combines up to 2% of its weight with oxygen and 4% of its weight with water.

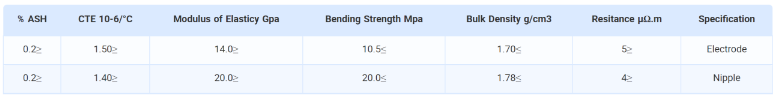

Graphite electrode:

According to international standards, graphite electrodes must be made from calcined petroleum coke (CPC). Needle coke production technology, as the main raw material of CPC, is available exclusively to countries such as China, USA, Japan and Germany. This has made the manufacture of graphite electrodes as the main consumable material in electric arc melting furnaces, the monopoly of developed countries. To produce graphite electrodes, needle coke powder is first molded and compressed with a vibrator. The formed electrode is then baked in an oven. After baking, a layer of bitumen is added to it. Finally, this product is again at a temperature of 3000 degrees Celsius and turns into graphite. After the production process, turning operations are performed on the electrodes. These electrodes are mostly produced in a cylindrical shape and after production must be cut in standard diameters. It is necessary to install a pin as a socket on the electrode head.

Reviews

There are no reviews yet.